- CAD CAM SOLUTIONS DRIVERS

- CAD CAM SOLUTIONS SOFTWARE

- CAD CAM SOLUTIONS TRIAL

- CAD CAM SOLUTIONS PROFESSIONAL

- CAD CAM SOLUTIONS SERIES

All of these headaches have gone away since we’ve started using Tebis: now we just take the CAD data from our customer, generate the vacuum clamping device using the Tebis wizard and clearly define the component position. This would play havoc with tight deadlines. Sometimes we would wait a week to receive the product back with the modifications required. Invariably, we would courier a product to be inspected by the customer and await approval to continue.

CAD CAM SOLUTIONS TRIAL

There was a lot of trial and error in generating a perfect NC program, which meant that there could potentially be a lot of scrap.

Another obvious benefit is that we don’t have to stop the machines to program them any more”.īrickles adds: "In the old days we would always question the accuracy of the end product, especially if it was a very complex component. Products assembled from multiple parts now just click together perfectly the first time, because we’re using the customers' own CAD data. In some cases, manufacturing components using Tebis is 75% faster than using conventional methods. But the advantages offered by implementing the Tebis system have far exceeded our expectations.

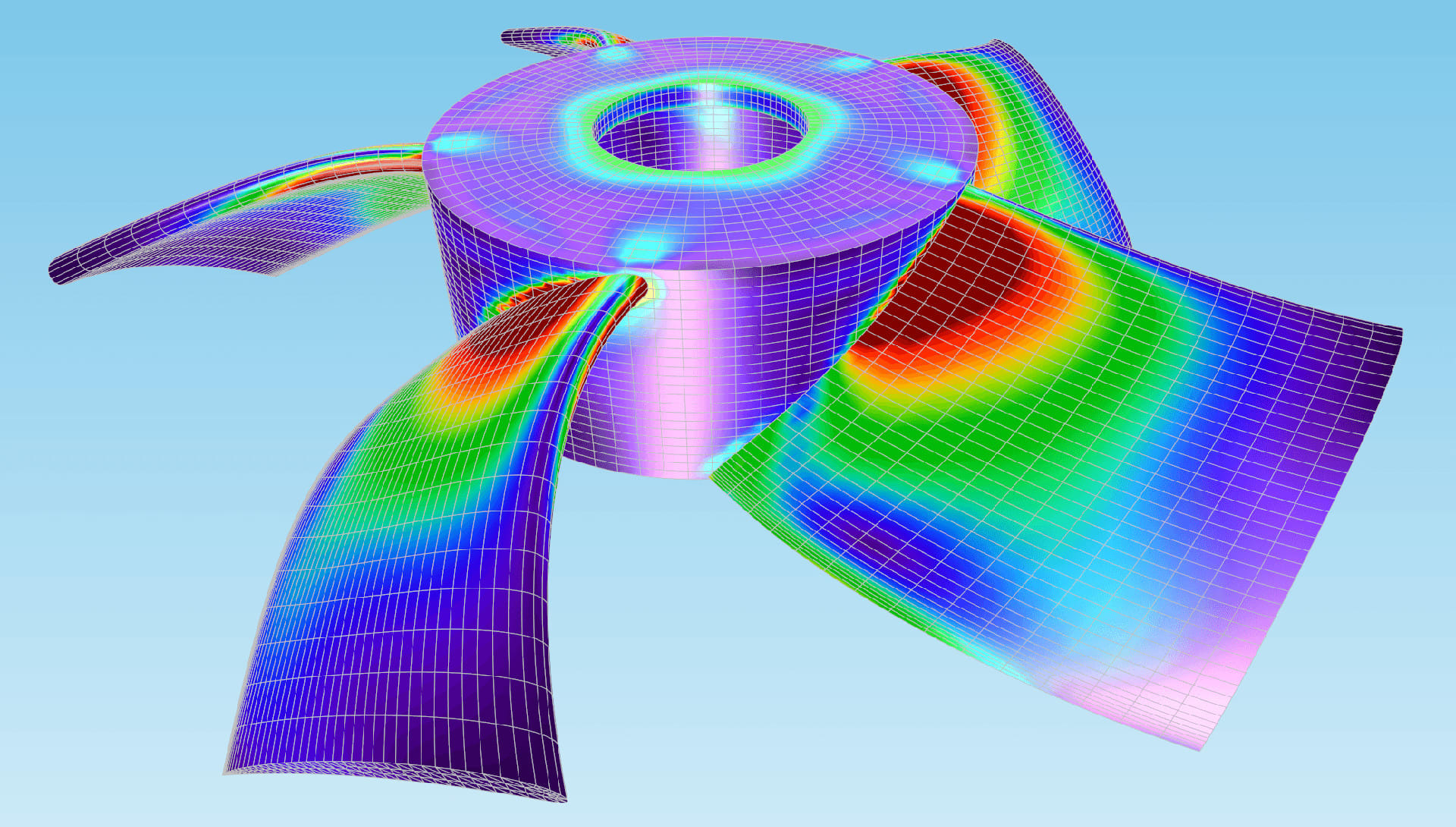

He explains: "At the time we didn’t know any different, and we thought we were quite efficient with our processes. Every product underwent several modification iterations during this process. In addition, he bears the main responsibility for keeping the 5-Axis Maka milling machines running at the highest possible capacity and ensuring that the NC programs are running problem-free.īefore using Tebis, Brickles and his team relied primarily on the teach-in method, just like other companies in the industry. As the chief engineer in the Engineering department, he is responsible for training the CNC operators and for all the tooling and fixture design. Jason Brickles knows the process chain inside out. The company uses Tebis CAD/CAM solutions in design and NC programming.

Ansini can supply anything from a single molded part, trimmed components, and complex assembled products – packaged and ready for distribution worldwide. Their portfolio also encompasses a comprehensive range of additional services including CNC routing, ultrasonic welding and leather and fabric trimming. The 12th Gen Intel Core i9 12900K CPU with 16 cores & 24 threads running at 5.2 GHz is our favorite highend CPU for most CAD/CAM/CAE and rendering workloads, providing maximum all around performance for a reasonable cost.Ansini, based in Mansfied, Nottinghamshire, is a thermoforming manufacturer with expertise in project management, tooling design, thermoplastic forming, CNC trimming, product development, testing and assembly. We carefully select the Intel processors used in our powerful CAD computers to maximize both single and multithreaded performance by striking a fair balance between high operating frequency and multi-core configurations.

CAD CAM SOLUTIONS SERIES

Many CAD program functions are largely single-threaded, benefiting from the high operating-frequency of our Intel Core i7, i9 and Extreme series processors, while simulation and rendering functions tend to benefit from more CPU cores and threads. To optimize CAD/CAM/CAE performance, all our Intel based desktop workstations focus on maximizing processor frequency while retaining plenty of CPU cores, leading to drastically improved performance for common multithreaded CAD/CAM and Engineering functions such as rendering, simulation, toolpath generation and extensive multi-tasking. Many Computer Aided Design and post-processing programs out-source computationally intensive tasks to the GPU, improving workflow, decreasing CPU overhead, and decreasing time to market, making powerful GPUs integral to our engineering and design workstations. Orbital CAD workstations place a specific emphasis on powerful and capable graphics by including the strongest GPU options within a given price range. Certain CAD programs benefit more from the higher spec, lower cost Nvidia RTX cards for their GPU accelerated tasks – contact us before ordering to ensure you’ll get the best possible GPU for your unique workflow.

CAD CAM SOLUTIONS PROFESSIONAL

These workstation GPUs are validated on hundreds of professional CAD/CAM/CAE and GIS applications to operate at the highest precision possible, leading to significantly increased productivity and truly professional grade results.

CAD CAM SOLUTIONS DRIVERS

Adobe, Autodesk, Dassault, etc) to optimize GPU drivers for those specific programs.

CAD CAM SOLUTIONS SOFTWARE

NVIDIA works directly with dozens of Independent Software Vendors (e.g. NVIDIA Quadro drivers are developed to maximize harmony between software and hardware in a way that goes far beyond what non-professional graphics cards require. We exclusively use NVIDIA Quadro and Nvidia RTX graphics cards on our engineering and CAD workstations.

0 kommentar(er)

0 kommentar(er)